Product Menu

- กว้าน

- ขาแขวนรอก

- ถังดักไขมัน

- ถังรักษาแรงดัน

- ริงโบลเวอร์

- เครื่องมืออุตสาหกรรม

- สินค้าอื่นๆ

- เลื่อย/เครื่องมือตัด

- อุปกรณ์ระบบบำบัดน้ำเสีย

- รอกสลิง

- รอกมือสาว

- เครื่องเติมอากาศใต้น้ำ

- โรลม้วนสาย

- ลูกลอย

- เครื่องมือ/อุปกรณ์ทำความสะอาด

- เครื่องเติมอากาศบนบก

- ปั๊มเครื่องยนต์

- รอกมือโยก

- เครื่องมือก่อสร้าง

- หัวจ่ายอากาศ

- สปริงบาลานเซอร์

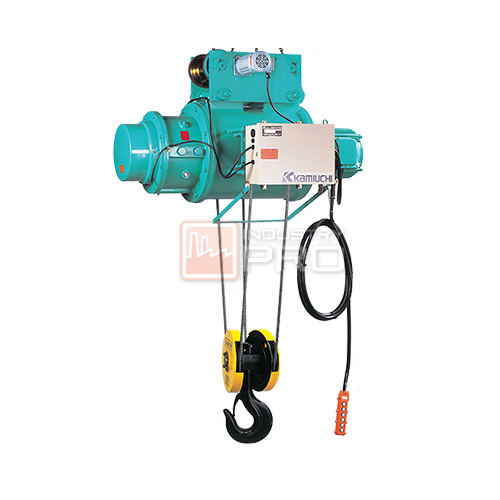

- รอกไฟฟ้า

- อินเวอร์เตอร์

- ปั๊มเฟือง

- เครื่องเติมอากาศผิวน้ำ

- เครื่องกวาดตะกอน

- เครื่องมือลม

- สวิตช์ควบคุมแรงดัน

- ปั๊มแช่ ปั๊มจุ่ม

- ปั๊มน้ำดี

- ปั๊มจ่ายสารเคมี

- ปั๊มสูบจ่ายของหนืด

- เครื่องพ่นไฟและหม้อไอน้ำ

- ปั๊มน้ำยาเคมี

- ปั๊มคอนเดนเสท

- ปั๊มน้ำ

- ปั๊มบาดาล

- ปั๊มอื่นๆ

- ถังเก็บน้ำ

- อุปกรณ์ทำสวน

- ปั๊มลมและอุปกรณ์ระบบลม

- เคมีภัณฑ์

- โครงสร้าง

- เครื่องเติมอากาศ

- ปั๊มลม

- พัดลมอุตสาหกรรม

- ปั๊มสุญญากาศ

- มอเตอร์ไฟฟ้า

- มอเตอร์เกียร์

- มอเตอร์ลม

- ปั๊มสูบน้ำมันจากถัง

- ปั๊มไดอะแฟรม

- ปั๊มน้ำแรงดันสูง

Menu